9 Simple Techniques For Electrical Panel Phenolic Labels

Wiki Article

Electrical Panel Phenolic Labels for Beginners

Table of ContentsA Biased View of Electrical Panel Phenolic LabelsA Biased View of Electrical Panel Phenolic Labels6 Simple Techniques For Electrical Panel Phenolic LabelsThe Best Strategy To Use For Electrical Panel Phenolic LabelsHow Electrical Panel Phenolic Labels can Save You Time, Stress, and Money.The 30-Second Trick For Electrical Panel Phenolic Labels

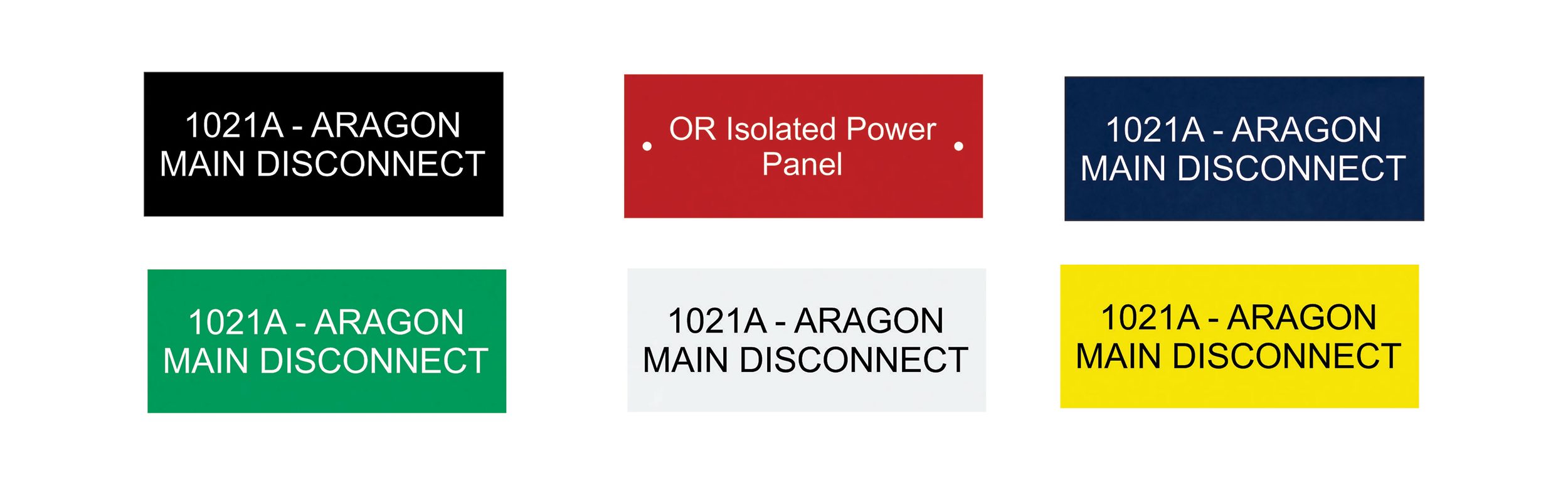

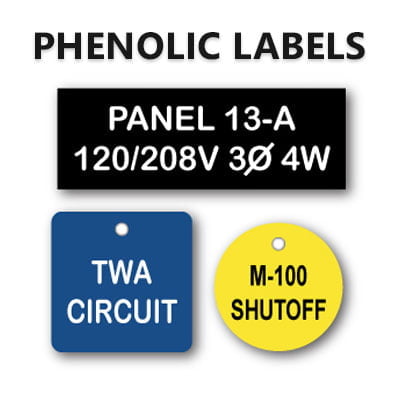

Phenolic labels supply a large range of advantages that make them optimal for usage in a host of circumstances. Review on as we take an appearance at four perfect applications for phenolic tags. Electrical Panel Phenolic Labels. The last point you desire anywhere near electrical power are metal labels.That's why phenolic tags are the ideal remedy for electric panels.

They're also highly scratch-proof, so your labeling will certainly be clear for years to come. Phenolic labels have no such problems.We additionally have a broad option of other types of tags and tags readily available. Inland Products has an experienced, experienced, and practical sales staff waiting to respond to any questions you might have.

Some Known Facts About Electrical Panel Phenolic Labels.

From: Cindy (CINDYM) [# 14] 9 May 2005To: Rodney Gold (RODNEY_GOLD) [# 13] 9 May 2005 Same below - if the specifications ask for phenolic, we need to use phenolic, despite how a lot we wish we could replace Romark instead. There are certain applications that just call for phenolic. Cindy MFrom: Jim (PUZZLEHEAD) [# 15] 9 May 2005To: Cindy (CINDYM) [# 14] 9 May 2005 There are absolutely applications where phenolic is the much better item.Once they are educated about the newer materials, my customers usually pick Rowmark's Ultra, Matte for their etched tags. I don't even provide any one of the non UV secure materials like the satins. Most of my work is for commercial applications and less than 1% of the tags I make are phenolic.

No one has ever before asked me to change any of the tags. Jim, From: Cindy (CINDYM) [# 16] 9 May 2005To: Jim (PUZZLEHEAD) [# 15] 9 May 2005 I hear what you are saying, and when we can we do relocate customers to the non-phenolic materials - Electrical Panel Phenolic Labels. So many are ignorant, which is our job - to let them know they have choices.

The Buzz on Electrical Panel Phenolic Labels

However, for the specifications that do not particularly mean it out, I inquire about useage and will certainly make referrals based on where the tag is going. We've been utilizing a great deal of lasered stainless tags additionally lately. I'm not a thrilled supplier of phenolic, but it does have it's place in our line of product.After speaking to an engraving shop owner a couple of days earlier, I was informed that, due to OSHA demands and NEC, he might not etch the labels that I asked for from his store since of the product I asked for and the application for which they were to be used. He went on to describe that plastic generates an extreme quantity of poisonous fumes and gasses (specifically naming CO as the primary issue) when it sheds, so we might not utilize plastic as electric labeling product and must, rather, use phenolic labels.

I don't want to place any of my professionals at threat by utilizing the incorrect tag type, yet the business I function for isn't going to approve a label material acquisition of an extra pricey kind just based on a shop owner's recommendation." Because we do not expect fire to exist in our substations where these tags click here now will be made use more info here of, I believe that typical plastic tags are plenty resilient.

Rumored Buzz on Electrical Panel Phenolic Labels

It is additionally worth keeping in mind that I work in a production setting with a great deal of old devices, a lot of which has been around because in the past much of these requirements existed so much of the job my technicians are doing currently is upgrading this old tools. Seems like this GC informing the proprietor of a restaurant, I do function in, that running PVC conduit within was prohibited.My substations are not typically occupied unless there's job taking place inside them and, if there was a fire in among them, the only individuals that would certainly remain in there with it are firefighters who are wearing breathing security. I feel that, if there's a fire in an electrical substation, there's probably lots of other things producing "hazardous fumes" that need to be stressed over besides the little plastic labels.

Some Known Details About Electrical Panel Phenolic Labels

You require to be a member in order to leave a comment (Electrical Panel Phenolic Labels)

From: Stunt Engraver (DGL) [# 3] 6 May 2005To: dollar [# 1] 6 May 2005 Dollar, I have been around this sector awhile. Enough time to realize there's no single formula for prices. Some cost per line; Others per letter. Some by 3-5 times material cost. My pointer, with the variety of plates you mentioned, is to have them upreared.

Some Known Incorrect Statements About Electrical Panel Phenolic Labels

If you don't possess a cutter grinder, make certain you have lots of added cutters on hand. Phenolic makes short work of a sharp cutter.015), obtain extra. You can basics engrave about 20 tags before you will certainly require to transform cutters. You might need to change cutters regularly, or you could get more tags than 20. As soon as your cutter begins to shed also a little intensity, you will certainly start to notice the tops of the letter disappear and you can not just make the cutter go deeper to offset it - transform the cutter as quickly as you observe this occurring.

Report this wiki page